As global temperatures continue to rise, clean energy solutions have never been more important. 2020 is on track to be one of the warmest years on record with the last 10 years being the hottest decade on record.

In 2018, more than three-quarters of U.S. greenhouse gas emissions came from the transportation, electricity, and industrial sectors. As many utilities and industries set carbon-free goals, they will require innovative, affordable technology to reach these targets and effectively decarbonize. TerraPower’s molten chloride fast reactor (MCFR) technology has the potential to provide just that – low-cost, clean energy for the future. TerraPower and Southern Company are working together to advance the MCFR technology. Partnership with an established utility, like Southern Company, offers a crucial perspective and expertise that positions the MCFR for successful commercialization.

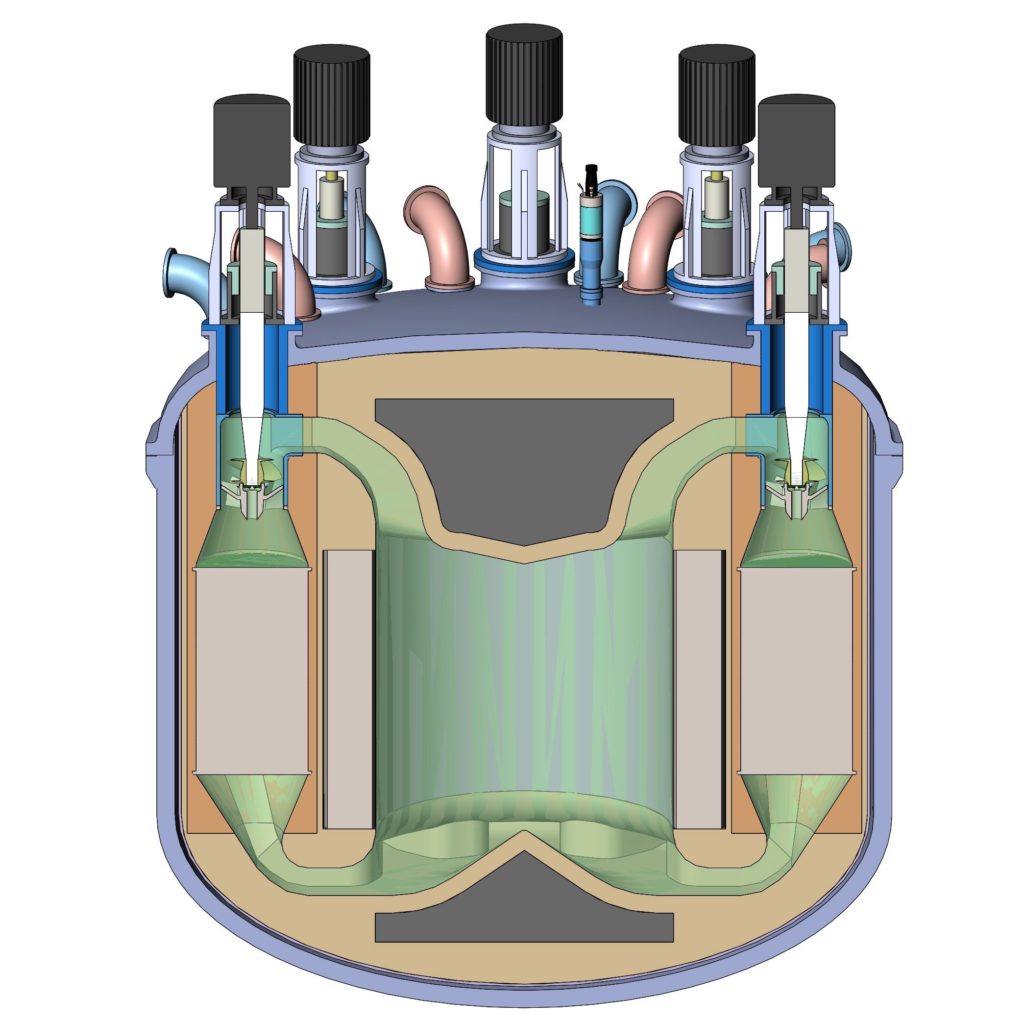

TerraPower’s MCFR is a type of molten salt reactor (MSR) – meaning molten, or liquid, salts serve as both the reactor’s coolant and fuel. The MCFR design specifically requires molten chloride salt, which allows for fast spectrum operation. In the fast neutron spectrum, neutrons are not slowed down (e.g. by colliding with water or graphite) and move very quickly making the fission reaction more efficient.

In MCFR cores, nuclear fission occurs and heats the fuel salts directly. The MCFR then distributes heat from the molten fuel salt through a heat exchanger to an inert salt in a second loop. Heat from the non-nuclear secondary loop is then safely used for electricity generation, process heat or thermal storage.

Key Features of TerraPower’s Molten Chloride Fast Reactor

The MCFR design is uncomplicated and allows for efficient, safe operation.

Simplified Architecture

TerraPower’s MCFR design is simplified making it easier and more efficient to build, and allows the MCFR to be used for multiple applications. The simplified architecture can scale based on different market needs without the need to redesign the reactor.

Continuous Fueling Process

Most reactors in use today need to be refueled every 18 to 24 months. TerraPower’s MCFR can be fueled as part of a continuous process that does not involve extended shutdowns, opening of the reactor vessel, or movement of numerous fuel assemblies.

Fuel Flexible

The MCFR is fuel flexible, meaning it can run on uranium of varying levels of enrichment. It is also a fast spectrum reactor, which opens new possibilities for waste reduction versus today’s light water reactors.

Natural Safety

When temperatures rise to limits set by design, molten chloride salt fuels naturally expand slowing the rate of the nuclear reaction. and shuts off the reactor without operator intervention.

When temperatures rise in molten fuel systems, the fuel naturally expands slowing the nuclear reaction. MCFRs are designed to take advantage of this natural stability, giving them the capability to shut-off without operator intervention if temperatures go beyond a design set-point.

Potential Uses of the Molten Chloride Fast Reactor

Addressing complex, global climate challenges will require decarbonization across industries. In the U.S., the top greenhouse gas-emitting sectors in 2018 were transportation (28%), electricity (27%) and industry (22%), according to the U.S. Environmental Protection Agency. It’s clear the U.S. needs energy solutions that provide abundant, carbon-free power and heat. TerraPower’s MCFR can help solve this challenge.

For example, many industrial processes, like manufacturing steel, require an immense amount of energy and heat. Traditionally, industries produced this heat by burning fossil fuels. The MCFR operates at higher temperatures than conventional reactors, thus generating electricity more efficiently and without emissions. Its unique design also offers potential for process heat applications and thermal storage.

What’s Next for the Molten Chloride Fast Reactor

Through private-public partnerships, TerraPower continues to advance its MCFR technology. In 2016, through the U.S. Department of Energy’s Advanced Reactor Competition (ARC), Southern Company and TerraPower began work on a $68 million project, funded by both a federal grant and investment from Southern and TerraPower, for continued research and development into the MCFR project. The ARC award’s main product is an Integrated Effects Test (IET).

Southern Company and TerraPower are working on the IET to learn how the MCFR will scale and behave at larger, commercially relevant sizes. The IET is expected to be commissioned and begin operating in TerraPower’s Everett, WA facility in mid-2021.

TerraPower’s innovative MCFR design expands the ability of nuclear technology to address carbon reduction in sectors including and beyond electricity. Its unparalleled design features make it a highly efficient, low-cost and carbon-free energy solution to help utilities and industries reach decarbonization goals.